Hollow Core Wall Panel

Lightweight, Fast Installation, World-Class Technology, Unlimited Design Possibilities

Designed according to ACI (American Concrete Institute), PCI (Precast/Pre-stressed Concrete Institute, Illinois USA standard). ISO 9001: 2015 certified.

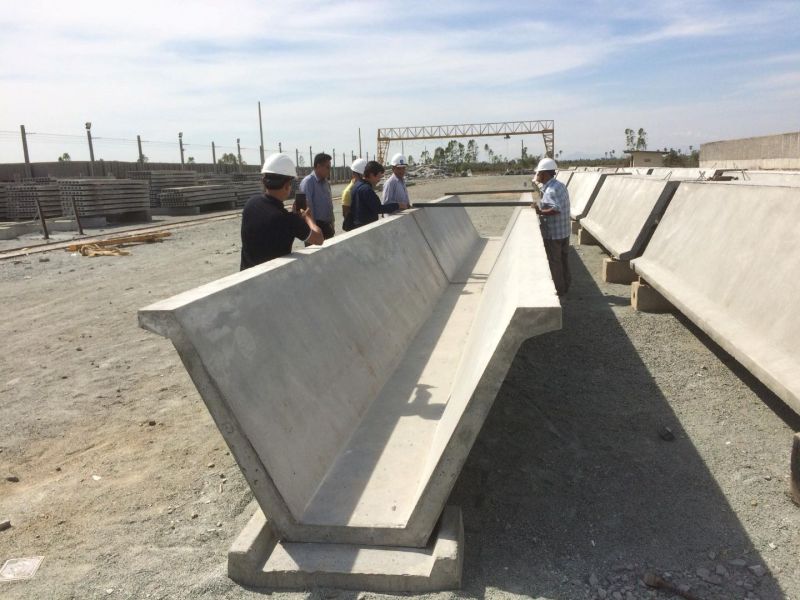

VCON hollow core wall panel is a precast, pre-stressed concrete with continuous voids. Using this unique wall will not only reduce building costs but will also reduce the overall weight of a structure. As an added benefit, the hollow core walls will eliminate the need to drill the slab for electrical and mechanical runs.

Durable and versatile, precast panels at a fraction of the weight with countless benefits.

Speed

VCON hollow core wall panels are delivered to your construction site install-ready. Acting as a building's complete envelope, including insulation, a moisture barrier and interior finish.

VCON hollow core wall panels have the potential to be erected in significantly less time than traditional cast in place.

Moreover, VCON hollow core wall panels can also help increase a project's vulnerability to unforeseen factors, such as poor weather condition and worksite accidents. By taking advantage of our controlled environment production, your are guaranteed quality, cost reduction, and speedy installation.

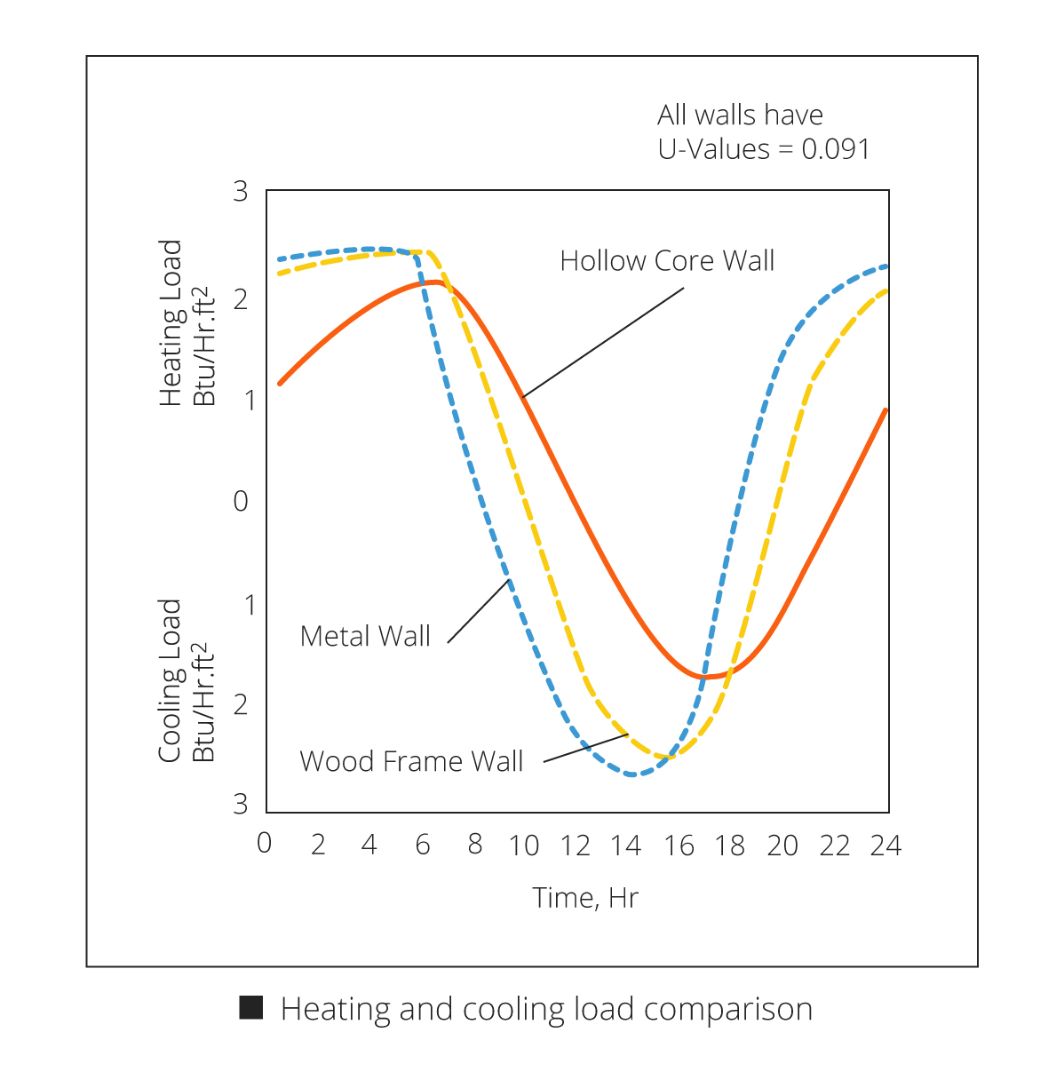

Energy Efficiency

Due to the hollow core wall's high thermal mass, the property thatenables materials to absorb, store and release heat, it possesses the ability to efficiently transfer large amounts of heat. Important to all, but especially in Southeast Asia, VCON hollow core wall panels keep buildings cool in the summer.

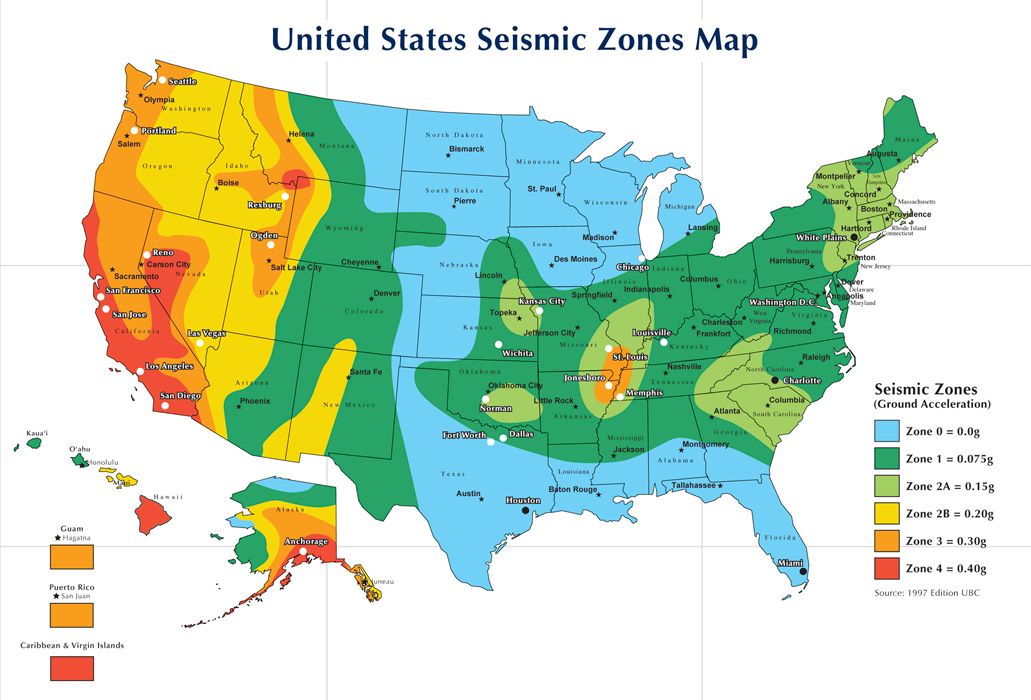

Seismic Resistance

A team of engineers tested a hollow core building on the world’s largest outdoor seismic shake table at the University of California San Diego. The results of this study showed that hollow core precast concrete damage was minimal (cosmetic damage) even after subjecting of intensity 50% higher than Zone 4 level input motion.

Fire Resistance

When it comes to fire resistance, VCON hollow core wall is far above other common building materials. Depending on thickness, ratings up to 4 hours endurance can be achieved.

Sustainability

Sustainability and environmental friendliness are extremely important to us.

With controlled environment production and install-readiness, VCON hollow core wall panels present the following reductions to a project's impact on the environment.

- Reduce amount of cement and water needed for production

- No need for on-site storage space

- Minimal debris and site disturbance

- Reduced labor and material, reduced waste

Low Maintenance

With quality control at the forefront of VCON's precast concrete production, VCON wall panels are nearly maintenance free building components.

With minimum maintenance comes reduced labor and repair costs

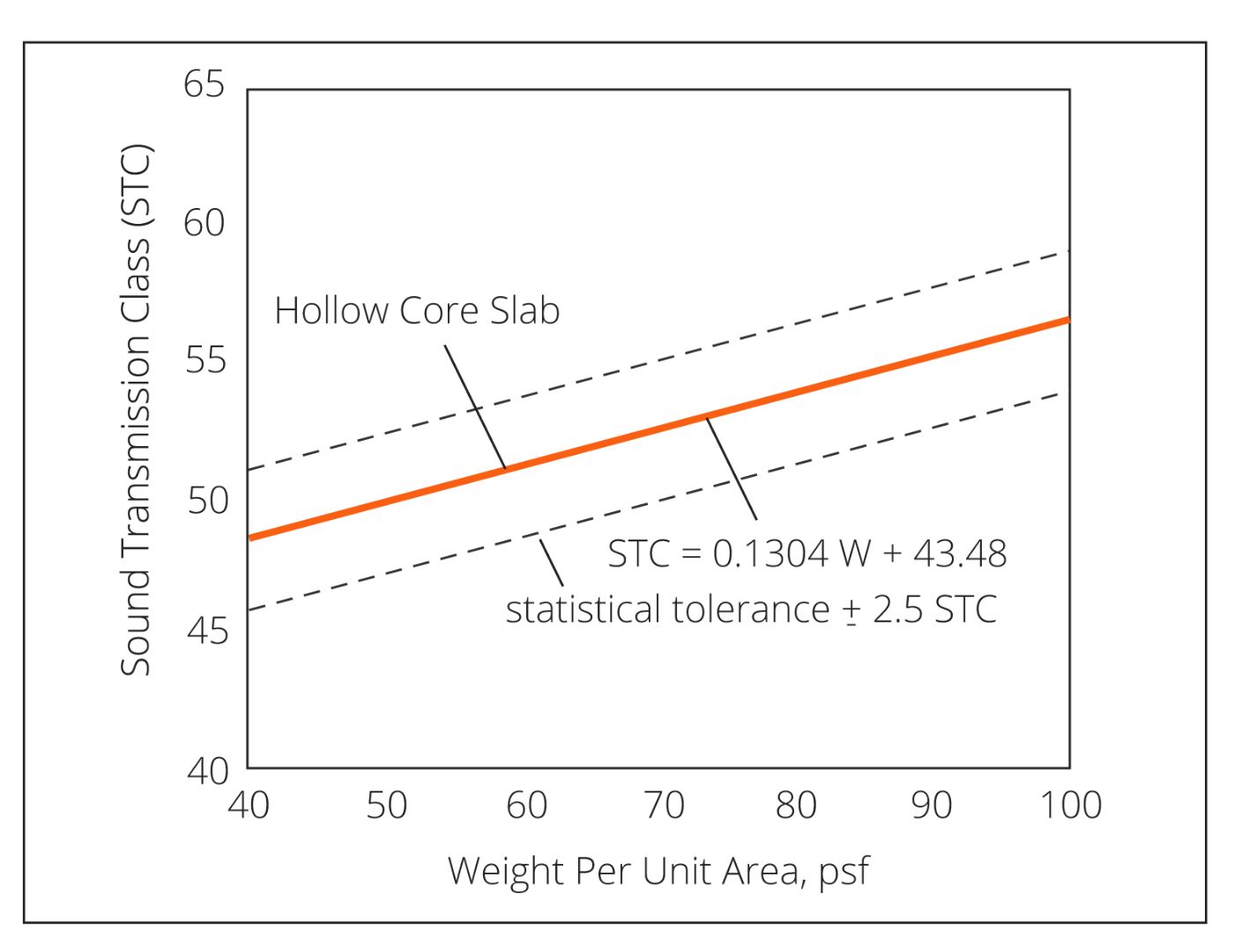

High Sound Resistance

VCON hollow core panels are superior to all other wall alternatives.

This feature proves extremely desirable in building such as schools, warehouses, shopping mall and offices.

Wall Systems Comparison

Brick Masonry System

- Not as strong as precast materials.

- Labor intensive.

- Brick masonry needs plastering done to finish a project which can raise construction costs.

- Efflorescence, cracking of concrete surface due to poor plastering skill.

Solid Wall

- Solid wall consumed 30% more concrete than hollow core wall, which leads to higher cost

- Solid precast concrete walls are heavy and large, which resulted in higher building foundation costs.

- Not as strong and durable as VCON hollow core wall Sealant is necessary.

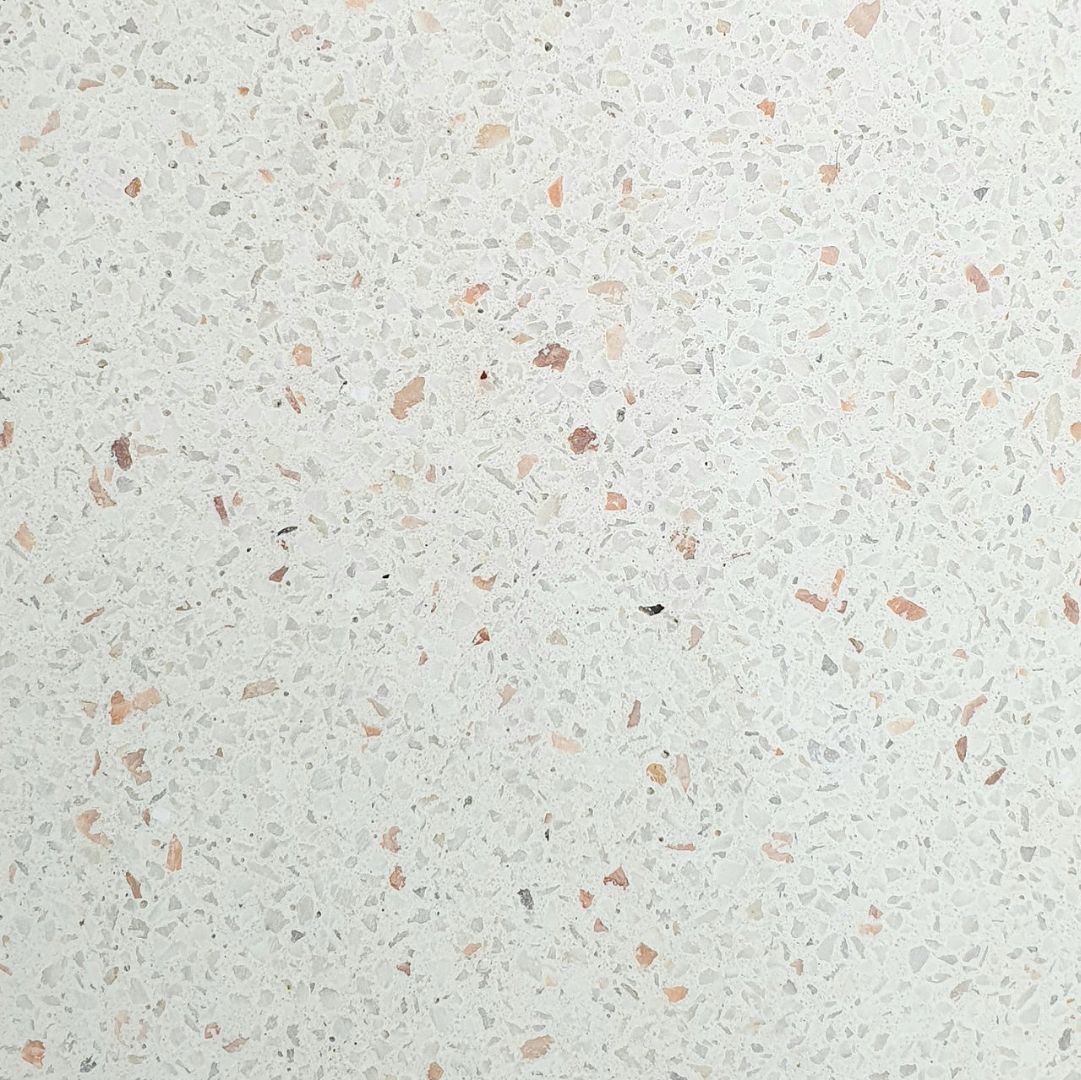

VCON Precast Concrete Finishes and Textures

For your vision truly come to life, aesthetic versatility is essential. While precast concrete itself brings unparalleled strength, durability, resilience, and cost savings to any construction project, precast concrete finishes and textures allow aesthetic creativity to seal the show. By combining color, exposure, texture, aggregate grade and sand type, a custom finish gives you a precast concrete structure with the unique look it needs to stand out.

Acid Etched

Black Bush-hammered Rib

Bush-hammered Rib

Bush-hammered Rib in Beige

Bush-hammered Rib in Concrete

Concrete Rib

Exposed Aggregate

Polished Rib in Beige

Polished Rib in Concrete

Sand-blasted Rib

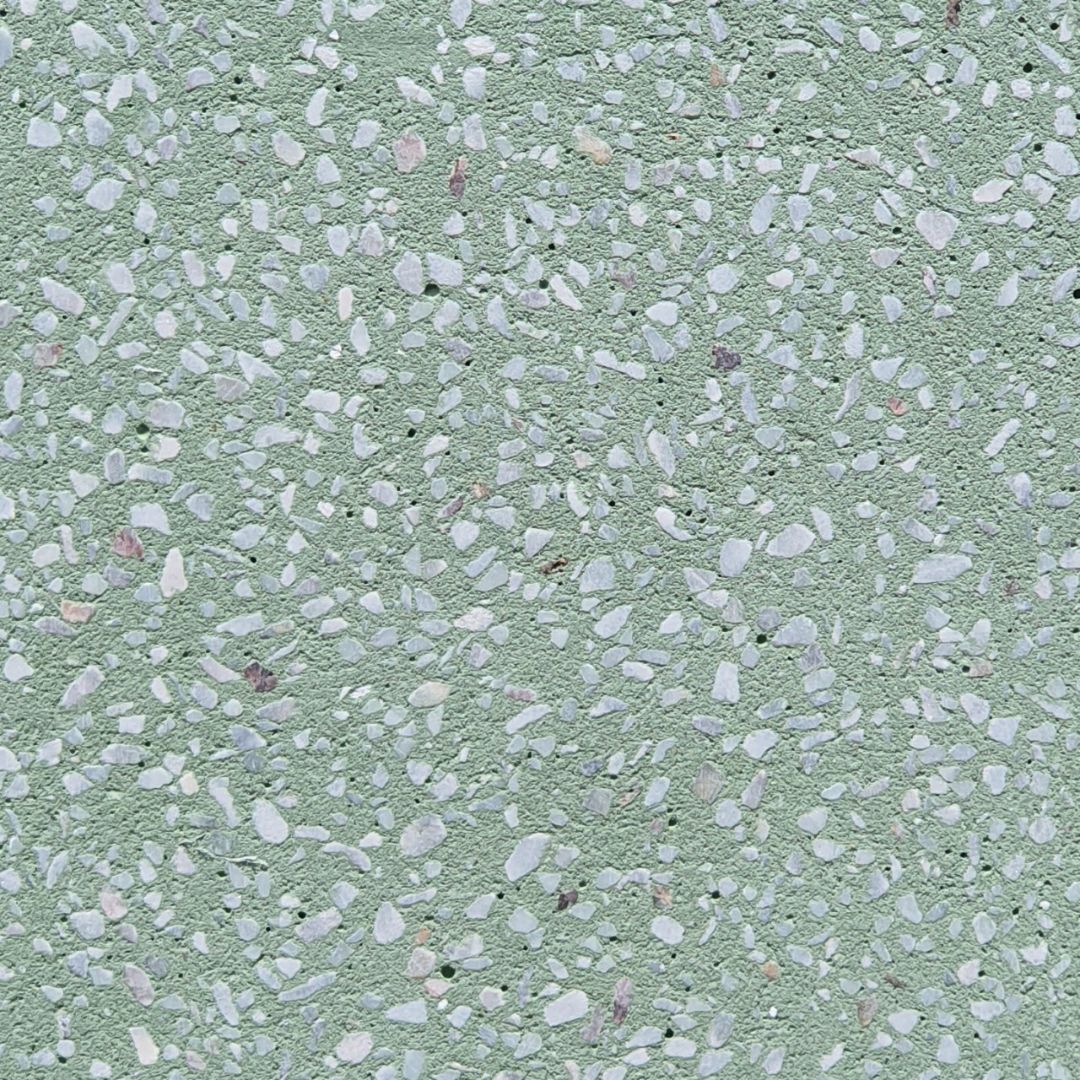

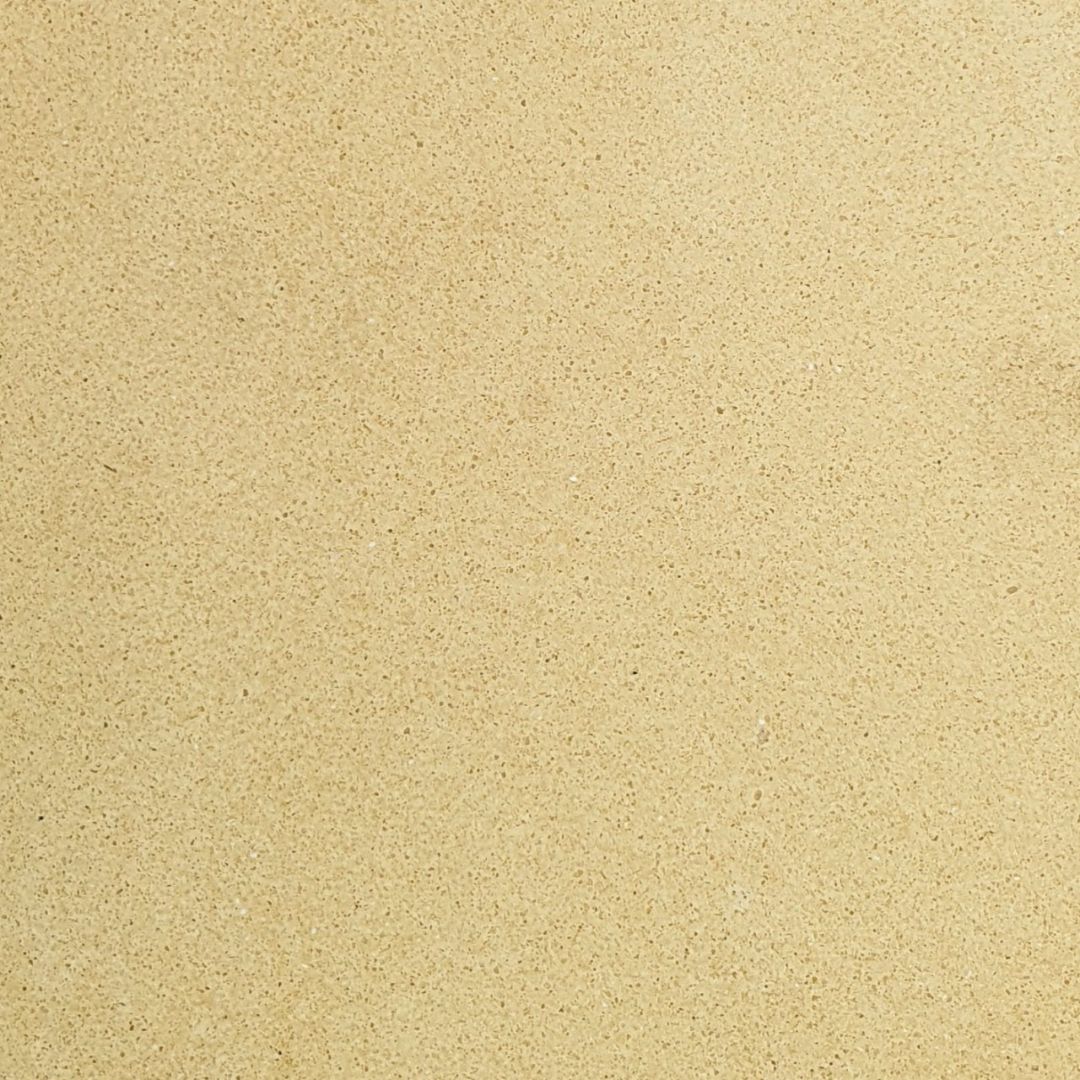

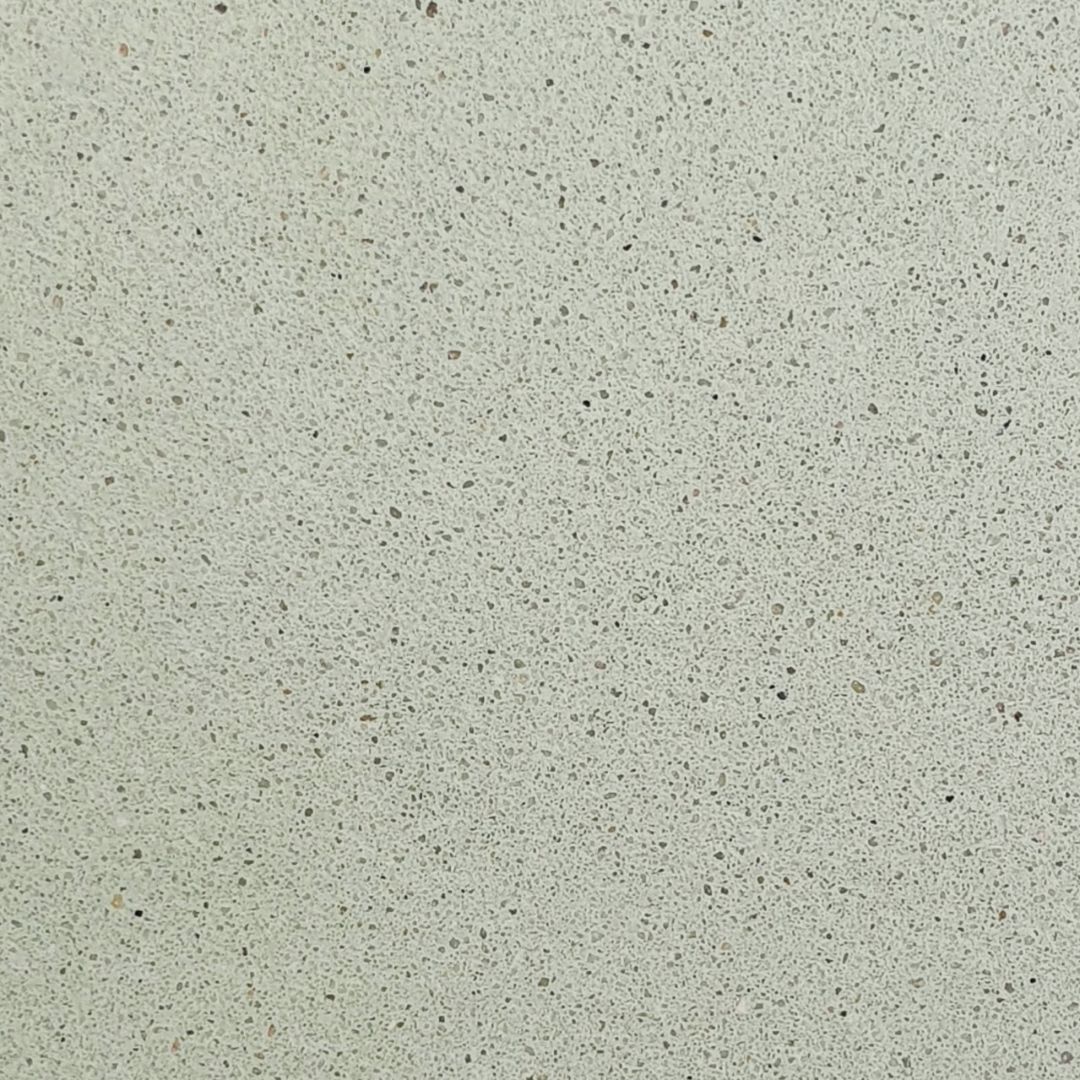

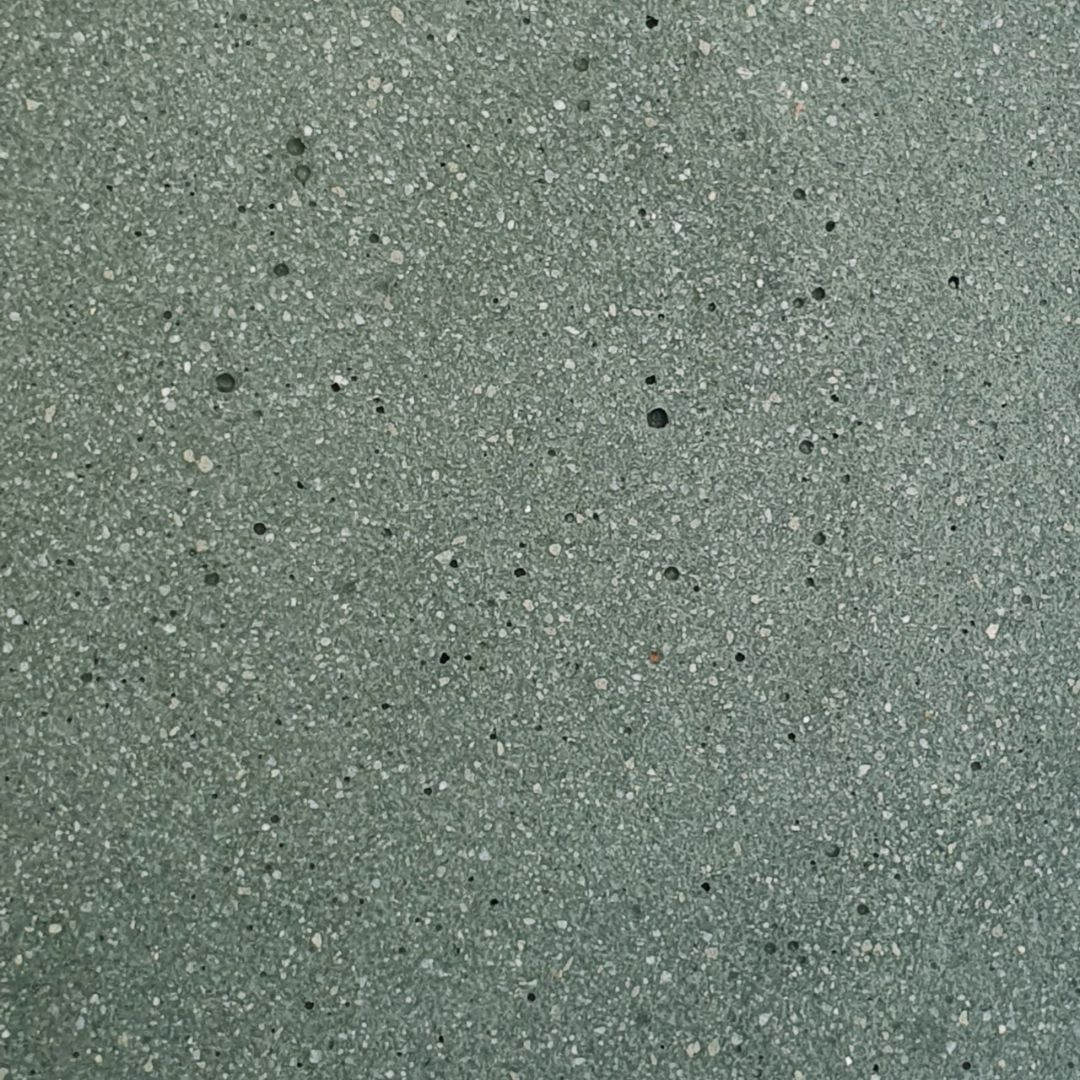

Terrazzo Polished

Apple Gum

Autumn

Berries

Brick

Caramel

Chai Latte

Cherry

Galaxy

History

Jet Black

Limestone

Mandarin

Mint Green

Mistletoe

Morning Beach

Olive

Oregon Pine

Quite Pink

Sahara

Tough Sahara

|

Available thickness |

11.5 cm |

13.5 cm |

16.5 cm |

21.5 cm |

|

Available width |

1.2 m |

1.2 m |

1.2 m |

1.2 m |

|

Available length |

1-4 m |

4-5.5 m |

5.5-7 m |

7-12 m |

|

*Approximate weight per square meter |

180 kg |

193 kg |

213 kg |

267 kg |

*Note : Weight/ m2 from calculation

|

EXTERIOR WALL |

BRICK MASONRY SYTEM |

SOLID PRECAST CONCRETE WALL PANEL |

VCON HOLLOW CORE WALL PANEL |

|

Construction speed |

5-10 m2/ day |

50-100 m2/day |

50-100 m2/day/team |

|

Length |

3 m |

4 m |

12 m |

|

Thickness |

10 cm |

10-20 cm |

11.5-21.5 cm |

|

Concrete strength |

20-35 ksc |

350 ksc |

400 ksc |

|

Fire resistance |

0.5-2 h |

2 h |

2-4 h |

|

Weight (10cm thick wall) |

180 kg/m2 |

240 kg/m2 |

180 kg/m2 |

Our Products